Flat Tempered Glass

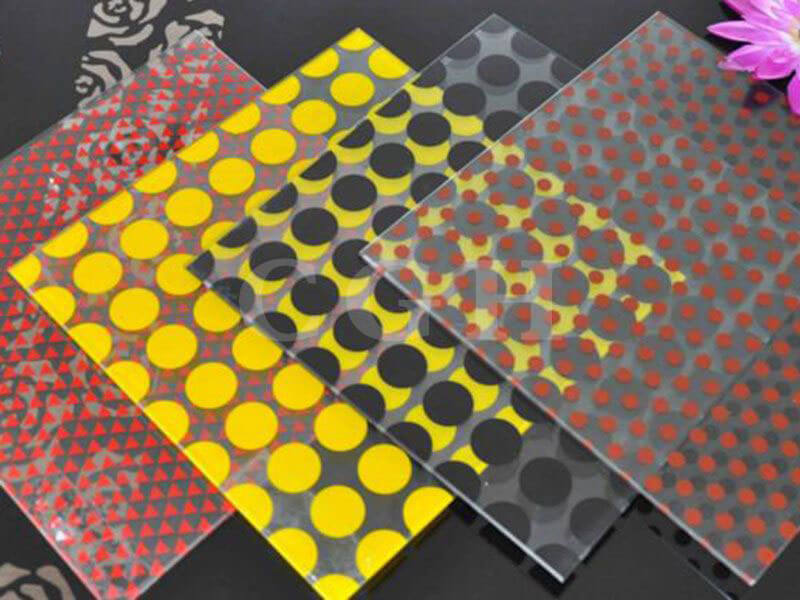

Color: clear, ultra clear, bronze, grey, dark blue, dark green, etc.

Thickness: 2 mm, 2.2 mm, 2.5 mm, 3 mm, 3.2 mm, 4 mm, 5 mm, 6 mm, 8 mm, 10 mm, 12 mm, 15 mm, 19 mm

Size: custom size acceptable, free with maximum size 3660*11000 mm

Standard: GB15763.2 (China), AS/NZS 2208 (Australia), EN12150-1 (EU) and ASTM C1048 (US)

Flat tempered glass, also known as toughened glass, is a type of safety glass that is designed to be stronger and more resistant to external forces than regular glass. This is achieved by creating compressive stress on the surface of the glass using chemical or physical methods.

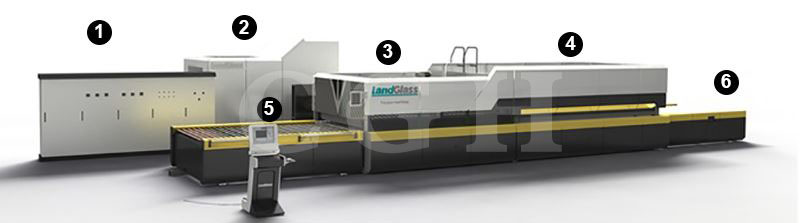

To make flat tempered glass, the glass is sent to a specialized furnace called a “tempering furnace”. The glass is heated to a temperature between 680-750℃ and then rapidly cooled. This process disrupts the molecular structure of the glass, causing compressive stress to be distributed on the surface while tensile stress is concentrated in the central layer.

The evenly-distributed compressive stress helps the glass withstand external forces such as wind pressure, temperature changes, impacts, and other stresses. If the external force exceeds the internal tension enclosed within the glass, the glass will shatter into many small, blunt particles that do not pose a risk of injury to humans.

Overall, flat tempered glass is a widely-used material thanks to its superior strength and safety features, and its common varieties include clear float tempered glass, ultra clear tempered glass, reflective tempered glass, tinted tempered glass, low-E tempered glass, patterned tempered glass, acid etched tempered glass, silk screen printed tempered glass, etc.

1. control panel

2. blower unit

3. cooling unit

4. heating unit

5. unloading section

6. loading section

Strength: our flat tempered glass is designed to be incredibly durable, with a strength and flexibility that is 4-5 times higher than ordinary glass of the same thickness.

Thermal Stability: our advanced technology enhances the thermal stability of our flat tempered glass, making it 3-5 times more resistant to sudden temperature changes compared to ordinary glass. It can withstand temperature variations of over 250°C, which effectively prevents thermal cracking. For example, our 5mm tempered glass can handle temperature differences of up to 200°C.

Safety: we ensure that our flat tempered glass shatters into small and blunt pieces if it is broken by external force, rather than sharp and dangerous shards.

As a kind of safety glass, flat tempered glass can be widely applied in the followings:

Doors, windows, curtain walls, interior decoration, etc. in the construction, construction template, and decoration industries.

Glass table tops, tea tables, and furniture accessories, etc. in the furniture manufacturing industry.

The household appliances manufacturing industry, as well as the electronic and instrument industry.

The automotive manufacturing industry and daily necessities industry.

Glass showers and bath enclosure glass in the shower room industry.